Industry and HMI are inextricably linked, especially in this era full of automation opportunities. Yet both are sometimes in a love-hate relationship and hardware that you have in mind does not turn out to be the “match made in heaven” that you had in mind as an engineer. Sometimes an out-of-the-box panel PC will be adequate for the intended application, but what if mechanical or technical requirements require customization?

Collaboration and growth in the supply chain through co-creation

For small-scale projects, improvisation is an option, but in the manufacturing industry it’s all about series production, on-time delivery and technical support. Reliable hardware is one thing, but working together in the chain and co-creation really makes the difference. This creates solutions that not only work, but are also future-proof.

Practice still appears to be the best teacher

When we look for practical examples with this starting point, Batenburg Applied Technologies is a leader in co-creation of automation hardware for the manufacturing industry in the Benelux. Over the years, the organization has grown into a unique trade combination of industrial distributor and design-in partner with in-house engineering and production capacity.

“By positioning ourselves in this way, we realize automation hardware together with customers that not only adds practical and aesthetic value, but also remains supported and manufacturable for years to come,” says Jurgen Jacobs, account manager HMI for Belgium. “Our expertise in displays, touch technology, embedded computing, wireless modules and thermal management comes from practical experience. This knowledge is constantly growing through new insights and solutions that surpass standard solutions.”

“It is by putting together systems in a smarter way, making prototypes and practical tests that valuable insights are created. We share this knowledge with the client and it is an important source for the further development of our team. This is how we create a real win-win for both parties involved. In addition, the customer knows that he remains the owner of the IP rights for his product,” adds Kjell Decorte, Country Manager for Belgium.

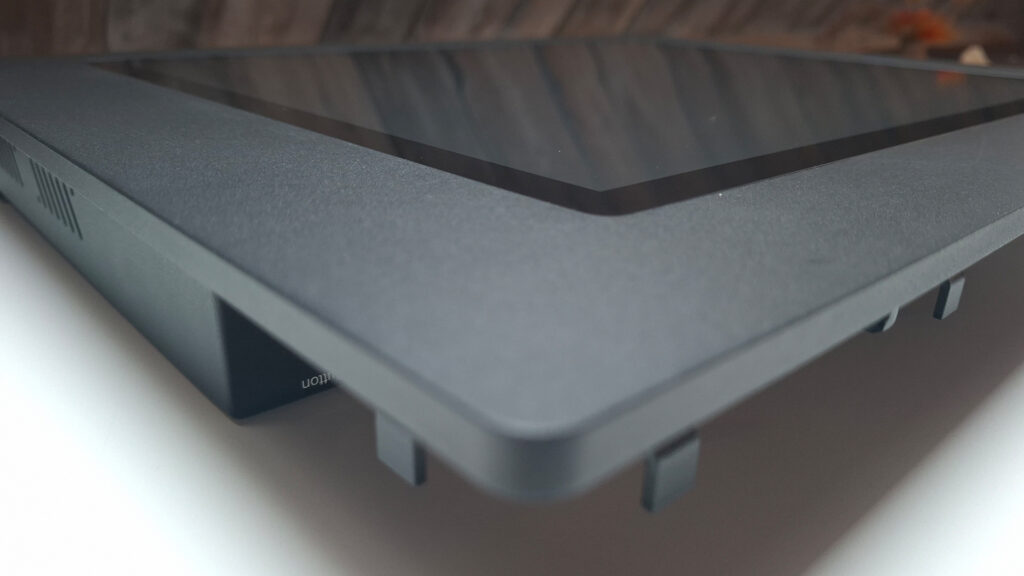

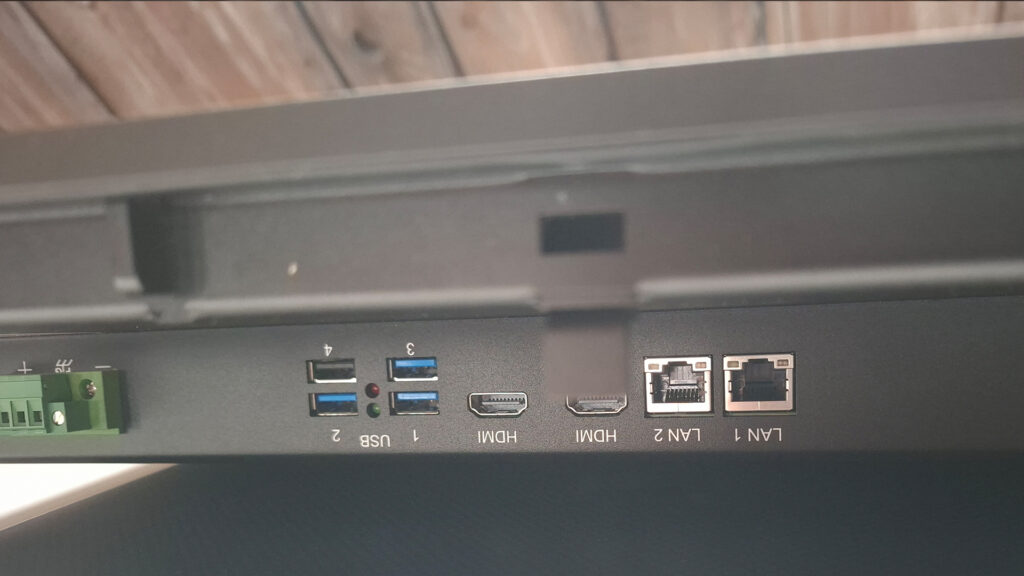

A redesign in the food industry as an example

For a machine builder in the food industry, a redesign of the HMI hardware became the starting point for customization. Where a standard Panel PC was previously sufficient, new wishes and requirements emerged: higher build quality, an adapted display size and attention to efficient installation and optimal hygiene. Further add guarantees for longevity, and then the choice for a partner that is more than a supplier is easily made. “Not just delivering, but thinking along, testing and guaranteeing customization for several years – that is where Batenburg Applied Technologies makes the difference,” Jurgen concludes.

The starting point for co-creation and automation hardware at Advanced Engineering 2026

During Advanced Engineering 2026, Batenburg Applied Technologies will show how OEM and ODM companies benefit from custom automation hardware, which originated from design-in and co-creation. The focus is on the scalable development of solutions and the guarantee of delivery over several years, both at component and system level. Visit booth 3026 on May 6 or 7 or the presentation during the conference program.