In modern mechatronic systems, actuator performance is no longer assessed solely on the basis of torque or speed. Energy consumption, controllability, dimensions, weight and intelligent monitoring have become defining characteristics of the next generation of motion systems. This article compares three representative drive architectures: a miniature Faulhaber 2232 BX4, a powerful Faulhaber MCS 3268 BX4 and a standard industrial 48V drive with low inertia under an identical 180° positioning cycle.

1. MOVEMENT AND ANALYSIS CONDITIONS

Each system performs a half turn (180° = π rad) in 0.25 s, then remains at rest for 1.0 s. Static torque required by the application: 0.1 Nm. The maximum angular velocity is 18.9 rad/s, with an acceleration of ≈ 228 rad/s². Inertia and standby losses are taken into account. The “standstill current” is taken into account during standstill.

2. INTERPRETATION OF ENERGY EFFICIENCY

Although the application requires less than 0.001 J of kinetic energy, the standstill current, zero kiss and acceleration torque are the dominant factors influencing efficiency.

- Dynamic control

All systems have an acceptable inertia ratio, but the MCS 3268 performs best and the bandwidth of dynamic behaviour and stability is high. The Faulhaber systems, with extremely low reflected load inertia, can accelerate quickly and achieve precise control with minimal current peaks. This is determined by the high input speed of the Faulhaber planetary gearheads and the high nominal speed of the low-inertia Faulhaber motors. Ideal for battery-powered systems, it reduces the need for oversized power supplies and cable sections.

- Mechanical efficiency

The 96% efficiency of the industrial unit’s gearbox exceeds the 82% efficiency of Faulhaber planetary gearboxes. With these light loads, the zero-backlash torque is decisive. At Faulhaber, this torque (6 to 10 mNm) is at least 6 times lower than with a traditional planetary gearbox (40 to 80 mNm). The difference in energy consumption at standstill is significant. Switching an EM brake on and off would take too long for this dynamic application and be anything but efficient.

3. INTEGRATION

Dimensions, weight, performance and efficiency

Electrification of existing pneumatic systems in automation and robotics applications requires several important performance indicators. Weight, dimensions and speed are decisive factors, and Faulhaber scores significantly better than standard industrial components in these areas. The efficiency and performance of an electric component is always much better and more stable than pneumatic actuators.

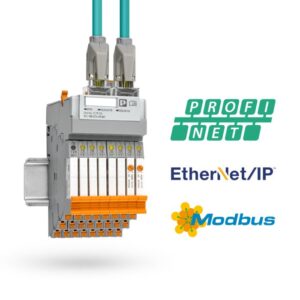

These days, the integration of these components into an industrial or robotics project is seamless. This is thanks to the supported CanOpen, Ethercat and Profinet networks.

By using the CiA402 motion profiles, this is even brand-independent.

Faulhaber has integrated a specific function that stores the maximum and average current for each movement. This allows the available data to be easily processed in an AI model that can make maintenance or service life predictions.