Verify, Assemble and Test PCBAs

We provide the Aster Technologies software tools to simulate a PCBA and the manufacturing/test machines in a digital environment.

Traditionally, manufacturing and test constraints are only considered at the end of the layout phase, prior to transfer of the CAD data to production. Due to board complexity, it is now mandatory to consider a validation stage at each step of the design and manufacturing phases.

The Testway Express software for Design for Test makes it possible to implement a Lean Test approach that produces a lower cost product whilst maintaining the highest quality.

TestWay has been developed to allow users to analyze each stage of the design to delivery workflow. This is achieved by the following stages:

– Electrical Design for Test – Verifies electrical DfT guide lines and includes standard and customer’s specific checks and requirements. Simulates the test strategy prior to the layout phase.

– Mechanical Design for Test – Optimizes test probe placement, estimates the test coverage and calculates the production yield and TL9000 initial return rates.

– NPI/CADCAM data export – Includes Automated Placement Machines, AOI, AXI, JTAG/Boundary Scan, Flying-probe Test, ICT and Functional Test. Exports the CAD data into the native format useable by the production and test machines.

– Test for Excellence – Compares the estimated coverage and completed test programs.

DfMExpress is a fully integrated DfM software enabling designers and electronic manufacturers to validate layout designs, prior to fabrication.

Design for Manufacturing (DfM) is the process of qualifying if PCB and PCBA are manufacturable and reliable at the best price:

– Design for MANUFACTURING: PCB fabrication is a complex operation, subject to a number of restrictions linked with cop

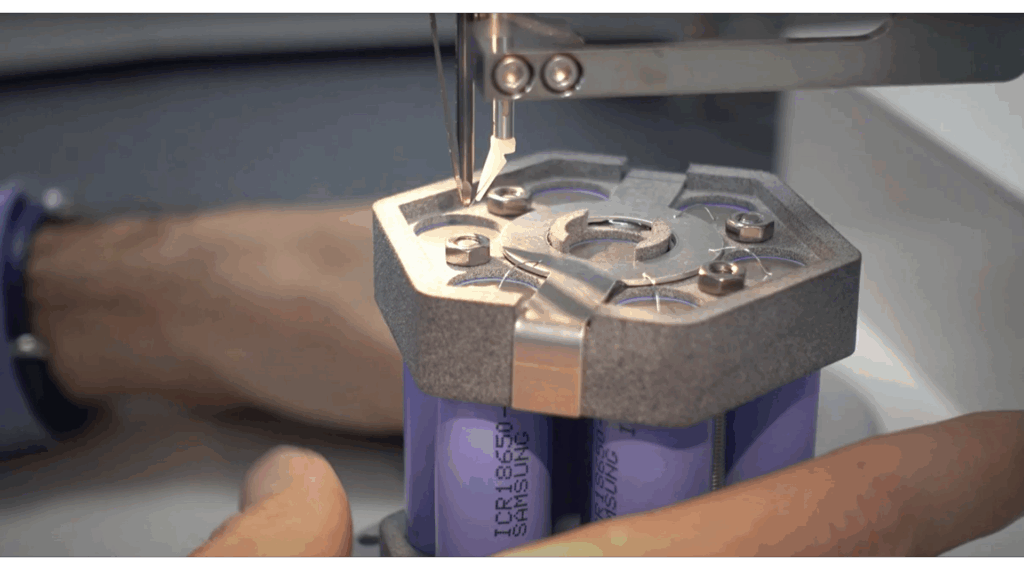

– Design for ASSEMBLY: The automated assembly process will combine THT and SMD components to be placed and soldered on the bare board.

Contact us for a demonstratuin!